Circular Economy

Circular Economy Targets

Meiji Group 2026 Medium-Term Management Plan

- Data target range or company leading initiatives

- 1: 7 domestic subsidiaries

- 2, 3: 5 domestic subsidiaries in the Food Segment

- 4: Meiji Co., Ltd.

- 5, 7: 11 domestic subsidiaries and affiliates in the Food Segment

- 6: 15 domestic subsidiaries and affiliates

| Major initiatives | Metrics | Results | Targets | Medium to long-term targets | ||

|---|---|---|---|---|---|---|

| FYE March 2025 | FYE March 2027 | FYE March 2031 | FYE March 2051 | |||

| 1 | Promote the reduction of plastic containers and packaging while promoting R&D for environmentally friendly materials | Rate of reduction for plastic use (total volume) (compared to FYE March 2018 as reference year) |

23.6% | 25% or more | 30% or more | |

| 2 | Reduce the amount of virgin plastic used by increasing the use of recycled plastics and biomass plastics | Rate of reduction for virgin plastic use (compared to FYE March 2018 as reference year) |

30.7% | 40% or more | 50% or more | 100% |

| 3 | Increase the ratio of recycled plastic used in PET bottles | Percentage of recycled PET used | 24.0% | 70% or more (FYE March 2026 target) |

100% | |

| 4 | Reduce food loss by improving supply and demand accuracy to reduce defective inventory, extending best-before dates, and indicating best-before dates in months and years | Rate of reduction for product waste in the food segment (compared to FYE March 2017 as reference year) |

25.0% | 50% or more (FYE March 2026 target) |

||

| 5 | Promoting food waste reduction along the supply chain from production (disposal of raw materials, etc.) to sales (disposal of returned products) | Reduction rate of food loss (compared to FYE March 2024 as year of reference) |

30.7% | 50% or more (FYE March 2031 target) |

50% or more | |

| 6 | Reduce final disposal volume by decreasing waste generation at factories, etc. | Recycling rate | 85.5% | 90% or more | Zero emissions | |

| 7 | Reduce food waste by recycling residual animal and plant waste (conversion into feed, fertilizer, methane fermentation, etc.) | Food recycling rate for the food segment | 96.5% | 95% or more | ||

Waste/ Recycled Amount

| Unit | FYE 3/2021 | FYE 3/2022 | FYE 3/2023 | FYE 3/2024 | FYE 3/2025 | ||

|---|---|---|---|---|---|---|---|

| Waste amount1 | Japan | ten thousand tons | 2.6 | 2.4 | 2.4 | 2.2 | 1.6 |

| Per unit of sales (Japan) | tons/hundred million yen | 2.4 | 2.2 | 2.5 | 2.3 | 1.6 | |

| Global2 | ten thousand tons | 3.0 | 2.8 | 2.7 | 2.7 | 2.3 | |

| Per unit of sales (Global) | tons/hundred million yen | 2.5 | 2.3 | 2.5 | 2.4 | 2.0 | |

| Hazardous waste emissions | ten thousand tons | 0.2 | 0.1 | 0.1 | 0.1 | 0.2 | |

| Recycled volume1 | ten thousand tons | 2.0 | 2.0 | 2.0 | 1.9 | 1.4 | |

| Final disposal volume (landfill) | ten thousand tons | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | |

| Reduction of food product waste | % | △29.3 | △34.1 | △31.5 | △26.8 | △25.0 | |

| Total weight of all food loss & waste | ten thousand tons | - | - | - | 2.5 | 2.0 | |

| Total weight of food loss & waste recycled | ten thousand tons | - | - | - | 2.4 | 1.9 | |

| Total weight of food loss | tons | - | - | - | 978 | 689 | |

| Per unit of sales | tons/hundred million yen | - | - | - | 0.12 | 0.08 | |

| Reduction of plastic usage | % | △11.7 | △16.0 | △18.3 | △22.1 | △23.6 | |

Independent Practitioner's Assurance

We have obtained the independent practitioner's assurance for the waste amount (Japan) in FY2024 Ernst & Young ShinNihon LLC to improve the reliability of the data.

Container and Packaging Life Cycle Management

Packaging plays an important role in protecting the quality of food and pharmaceutical products, as well as in providing product information to consumers.

The Meiji Group designs the packaging in an environmentally friendly manner. To minimize the input of new resources, we reduce the amount of materials used and devise product packaging that is easy to recycle. In addition to the 3Rs (Three Rs), we work actively to utilize recycled materials and materials made from plant-derived sources and other renewable resources, pursuing “Renewable” as a fourth “R.”

We select plastics, paper, glass, aluminum, steel, and other optimal materials in conjunction with the nature of the product in question, striving to ensure all packaging are sustainable. We also pursue research and development to enhance the functionality of packaging and quality retention to extend shelf life and provide other benefits.

Further, we strive in collaboration with the government and other external parties to establish systems for collecting used packaging. In this way, we contribute to the creation of circular economy.

Packaging Initiatives

To utilize precious resources without waste, we pursue reduction of the volume and thickness of our packaging and containers while maintaining product quality. In particular, we are strengthening our efforts to recycle plastics in order to solve the problem of marine pollution caused by plastic waste. In May 2020, we set a target to reduce the volume of plastics used in containers and packaging by 25% or more (compared to FY2017) by FY2030. In June 2020, we established the Meiji Group Plastic Resource Circulation Policy and have been steadily working toward this goal. As reductions have progressed at a pace exceeding the original target, in March 2024, we revised the target upward to achieve a reduction of 30% or more (compared to FY2017) by FY2030.

In addition, we have drafted new targets through which we will aim to reduce our new use of petroleum-based plastics to half of FY2017 volume by FY2030 and to zero by 2050. Furthermore, as of 2022, 80% of the containers and packing used in Meiji Co., Ltd.’s products (60% for plastic containers and packaging) are based on recyclable design. We will further aim for 85% recyclable design for containers and packaging by FY2030 (65% for plastic containers and packaging) and 100% by FY2050.

As specific examples of our initiatives, we pursue reduction of the weight of plastic (PET) bottle used in our products, reuse and recycle plastic utensils used in storing and transporting our products, and expansion of the use of recycled plastics and plant-based plastics for product packaging bags and attached straws.

Containers and Packaging Recycling Initiatives

The Meiji Group consigned recycling of containers and packaging of sold products to the Japan Containers and Packaging Recycling Association under the Containers and Packaging Recycling Act in Japan.

| Unit | FYE 3/2021 | FYE 3/2022 | FYE 3/2023 | FYE 3/2024 | FYE 3/2025 | |

|---|---|---|---|---|---|---|

| Plastic | t | 18,840 | 18,410 | 18,852 | 18,162 | 16,841 |

| Paper | t | 24,719 | 24,071 | 22,870 | 22,073 | 21,531 |

| glass bottles | t | 564 | 488 | 506 | 502 | 523 |

| PET bottles | t | 9,291 | 9,192 | 7,366 | 7,340 | 7,031 |

| total | t | 53,414 | 52,162 | 49,595 | 48,077 | 45,926 |

| Recycling implementation fees | JPY million | 6001 | 6052 | 7453 | 7154 | 6895 |

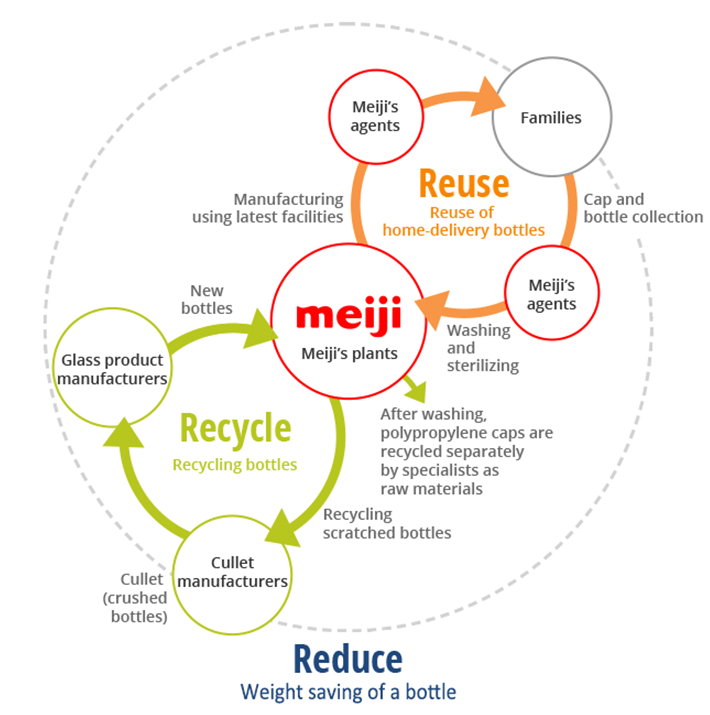

Initiatives to Reduce, Reuse and Recycle Bottles

Meiji Co., Ltd. reuses and recycles the delivery bottles used in our home delivery service. Our agents collect delivery bottles after consumers have finished with the product, after which the bottles are cleaned at our factory for reuse. After cleaning, polypropylene caps are recycled into cushioning materials and plastic bags by a specialized company. These plastic bags are utilized within Meiji Group's facilities as garbage bags and for waste storage, achieving internal resource circulation.

In pursuit of these activities, we encourage consumers to participate in collecting bottles as an environmentally friendly activity. Of course, delivery bottles will become damaged during the cycle of use and reuse. These bottles are crushed and remolded to be recycled as new bottles*. We are reducing the weight of delivery bottles, and we are also endeavoring to reduce the amount of glass used.

An Example of Using a Plastic Bag Made from Recycled Bottle Caps

| Unit | FYE 3/2020 | FYE 3/2021 | FYE 3/2022 | FYE 3/2023 | FYE 3/2024 | FYE 3/2025 | |

|---|---|---|---|---|---|---|---|

| Collection rate for delivery bottles | % | 97.7 | 99.5 | 99.3 | 99.7 | 99.7 | 98.0 |

Initiatives to Recycle PET Bottles

Recycling PET Bottles for Delivery

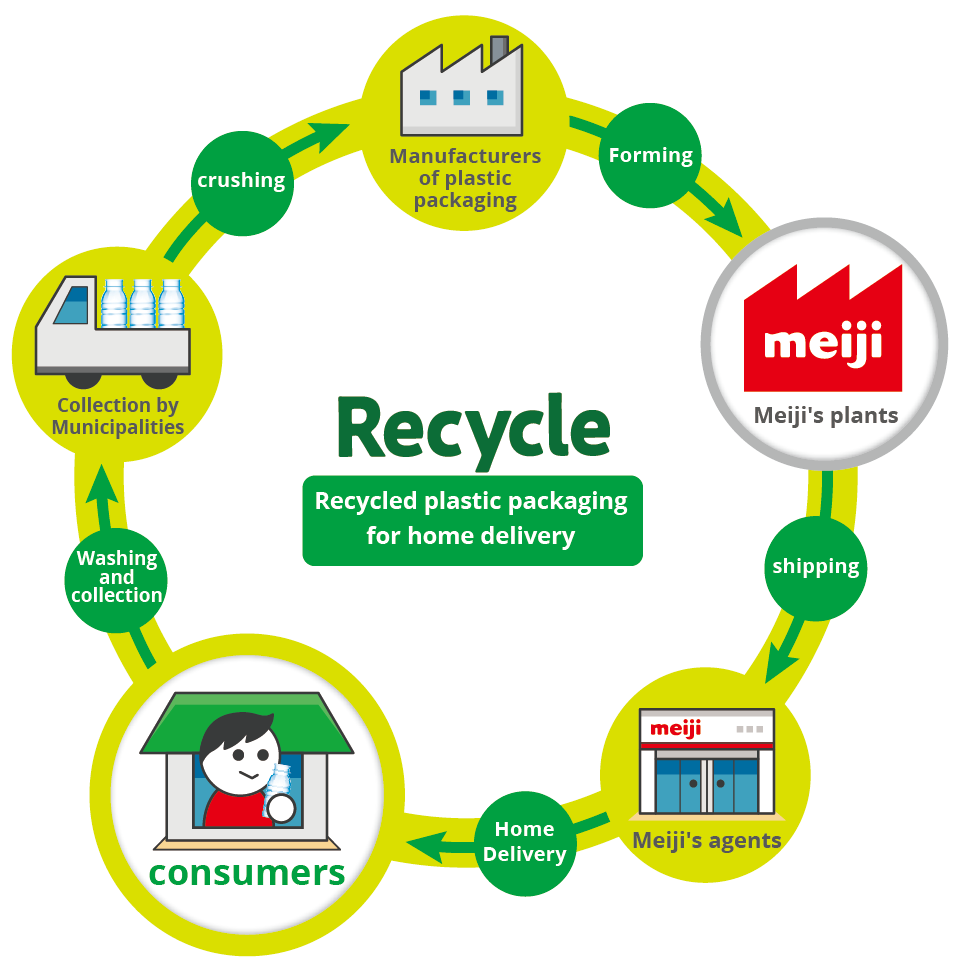

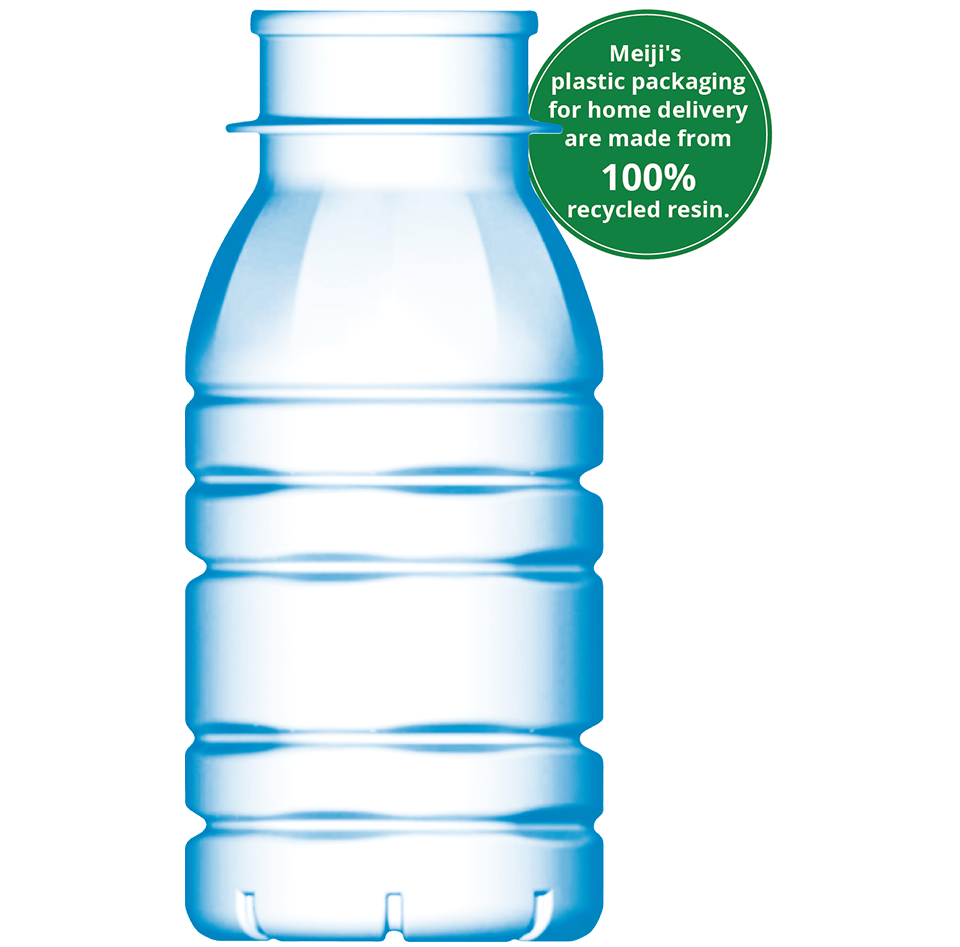

Plastic packaging used exclusively for home delivery are made of 100% recycled plastic resin, and new plastic packaging are made from used plastic packaging.

Municipalities collect plastic packaging used for home delivery after use. Some of these packaging are crushed at a plastic packaging factory to become raw materials for new plastic packaging, which are then formed into plastic packaging and shipped to our plants. This approach reduces the use of petroleum resources and reduces CO2 emissions.

“Bottle-to-Bottle” Horizontal Recycling through a scheme based on an industry-government-corporate partnership

In January 2025, the Meiji Group entered into agreements with Warabi City, Toda City, the Warabi-Toda Sanitation Center, and the Suntory Group to implement "Bottle-to-Bottle" horizontal recycling. A similar agreement was signed with Inazawa City and the Suntory Group in February of the same year. Under these agreements, used PET bottles collected in each city will be recycled and repurposed as PET bottle containers for both Meiji and Suntory Group. This initiative represents a collaborative effort between industry, government, and corporate to achieve horizontal bottle-to-bottle recycling. Through these efforts, we aim to enhance plastic resource circulation and contribute to the realization of a circular economy.

Initiatives to Recycle Used Plastics

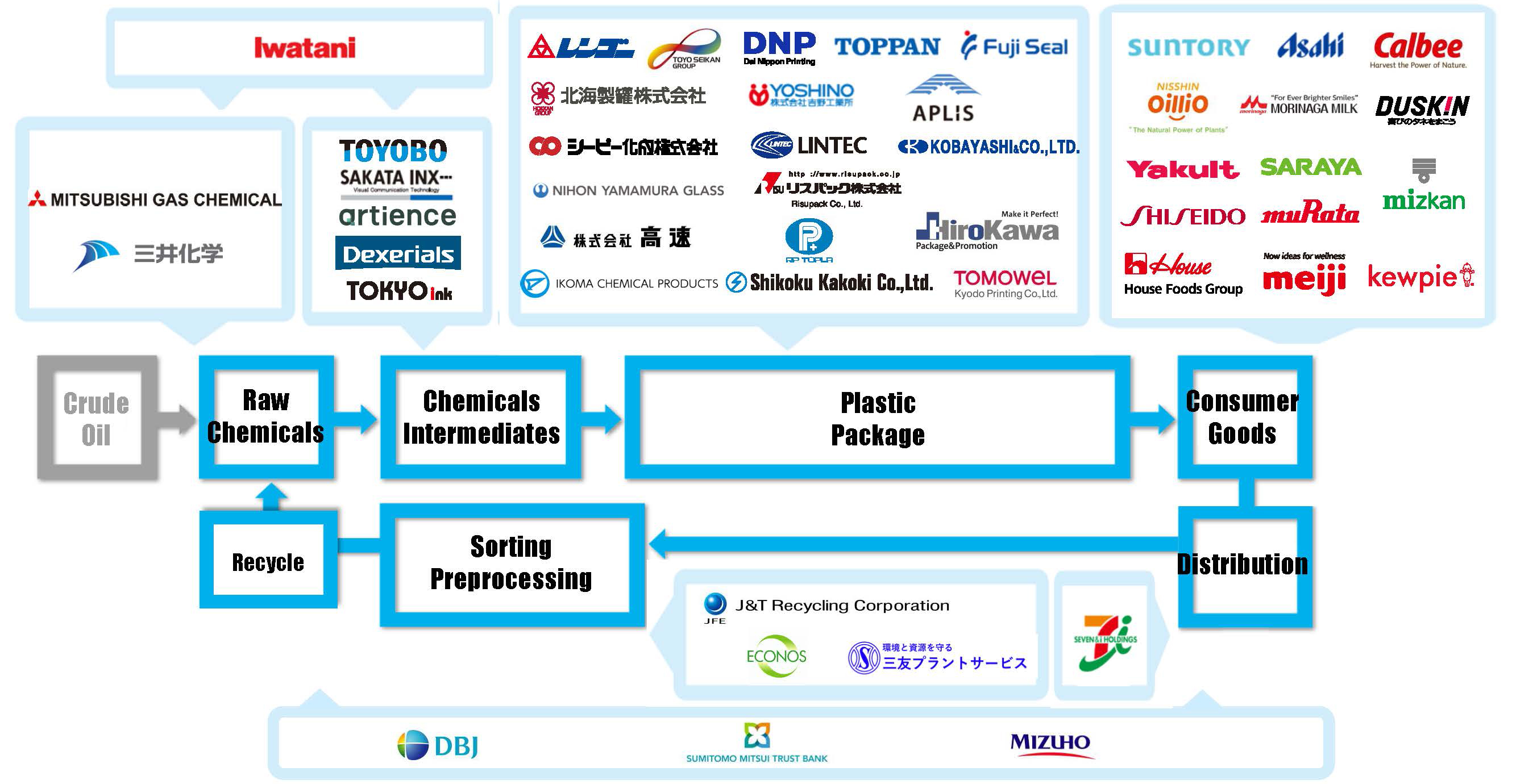

In February 2025, Meiji Co., Ltd. invested in R Plus Japan Ltd., a joint venture dedicated to the recycling of used plastics, as part of its commitment to addressing plastic-related issues. Through participation in this joint venture, Meiji aims not only to reduce plastic usage but also to enhance the recycling of used plastics, thereby contributing to the realization of a sustainable society as an integral part of the value chain.

[Participating companies]

Paper packaging Recycling Initiatives

The Meiji Group conducts "Paper Packaging Recycling Campaign" twice a year as part of its ethical promotion activities for its domestic employees. The paper packaging recycled through this campaign are converted into tissue boxes and toilet paper and they are donated to people in need. In addition, recycling paper packaging reduces CO2 emissions compared to simply incinerating them, hence this campaign has been registered as the "Decokatsu* Declaration" on the website of Decokatsu, which is promoted by the Ministry of the Environment.

Switching from plastic cups to environmentally friendly containers

In January 2021 production of our protein brand Savas' plastic cap began progressively switching to a more environmentally-friendly mix of 10% bioplastics. The packaging now carries Japan Organics Recycling Associationʼs "Biomass Mark."

Switching to a bioplastic mix for plastic straws attached to our products

Every year make use of around 650 million plastic straws for attachment to drink products. From February 2021 we began progressively switching to a mix of 5% bioplastics.

Examples of products with attached straws

Reduction of Food Loss

"Food Loss" refers to food that is still edible, but that is thrown away by manufacturers, retail, the food service industry, or by households. According to estimates in FY2022 by the Ministry of Agriculture, Forestry and Fisheries and the Ministry of the Environment, 4.72million tons of food is wasted domestically each year. The Meiji Group is aware that food loss is part of a serious societal problem and is taking the following steps, in line with government guidelines and industry association policies.

Definition of Food Loss

The Meiji Group defines food loss as food waste including inedible portions that has been processed and disposed of by landfill, incineration, or other means, excluding those that have been converted into feed, fertilizer, methane, mushroom beds, fuel and reducing agents by carbonization, fats, oils and fat products.

Initiatives to Reduce Food Loss

The Meiji Group is promoting to reduce food loss in various ways.

Reducing Dead Stock via Improved Demand Planning

Our manufacturing and sales divisions are cooperating to put together demand plans, taking into account various data, such as past sales and upcoming sales promotions. We are into account various data, such as past sales and upcoming sales promotions.

Changes to Best Before Date Labelling

We are progressively changing our food labelling from "Year/Month/Day" to "Year/Month".

We expect this switch to "Year/Month" labelling to enable greater coordination between production, delivery, and sales divisions. Thus, we are anticipating reduction in food loss and improvement in logistical efficiency throughout our entire supply chain.

From February 2020, we have changed the best before date of around 120 shelf-stable products, including frozen products, with long-term (at least 1 year) expiration dates over to "Year/Month" labelling.

Extending Best Before Dates Without Sacrificing Quality

We are extending the best before dates of certain confectionaries, drinks, nutritional products, and prepared foods where scientific and sensory analysis has shown it will not affect quality. This will help us reduce waste from expired, but otherwise safe and edible products.

| Products | Food Labelling (Best Before Dates) |

|---|---|

|

Infant formula Meiji Hohoemi RakuRaku Cubes (small box) and other 9 products

|

18 months → 24 months |

Thanks to impeccable hygiene on the production line, and our new freshness-ensuring cartons (made from light-blocking materials, and filled to the brim), Meiji Oishii Gyunyu's best before date has been extended.

| Products | Food Labelling (Best Before Dates) |

|---|---|

Meiji Oishii Gyunyu

|

15 days from date of production → 19 days from date of production |

| Products | Food Labelling (Best Before Dates) |

|---|---|

|

Meiji Hokkaido Tokachi Camembert Cheese and other 4 products

|

180days → 220days |

|

Meiji Hokkaido Tokachi Jukusei Sanshu no Cheese and other 1 product

|

100days → 120days |

| Products | Food Labelling (Best Before Dates) |

|---|---|

|

Chocolate Meiji Milk Chocolate and other 14 products

|

12months → 14months |

|

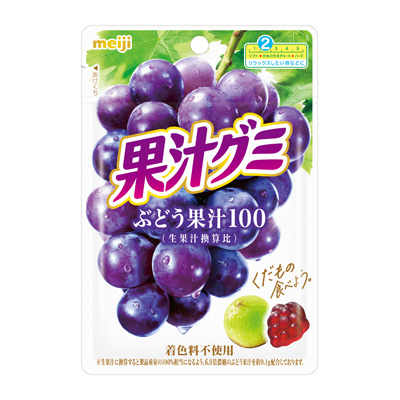

Gummy Kaju Gummy Grape and other 13 products

|

10months → 12months |

| Products | Food Labelling (Best Before Dates) |

|---|---|

|

Amino Collagen and other 4 products

|

18months → 24months |

Reducing Food Losses through Recycling

Of the approximately 25,000 tons of food waste generated from our domestic food business activities, and 95% of them is recycled. This recycling primarily involves converting the waste into animal feed, fertilizer, or methane gas through methane fermentation. The main focus of the feed conversion is producing feed for pigs, but some of it is also utilized as feed for cattle, chickens, and fish.

Reducing Food Waste along the Supply Chain

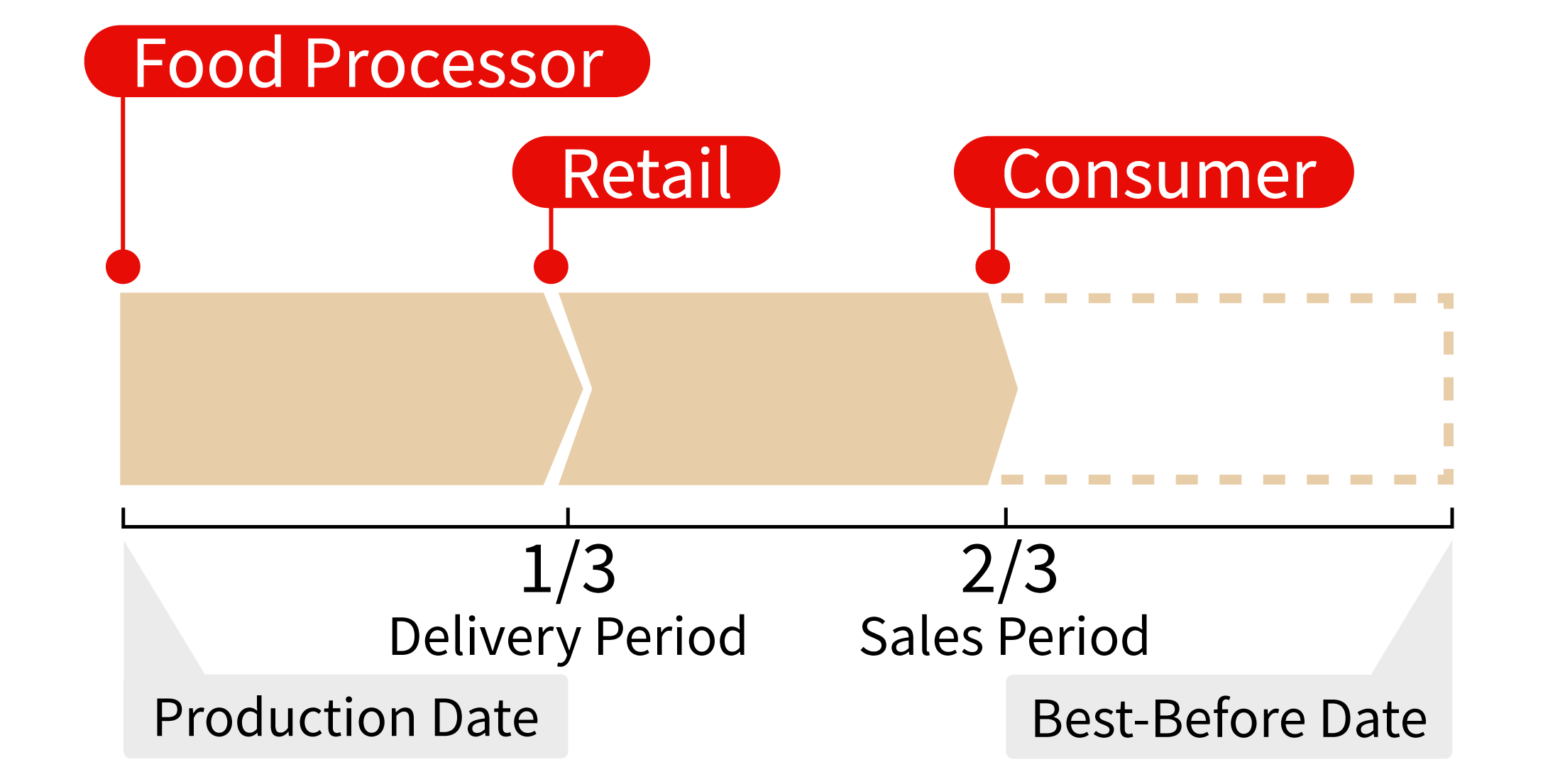

Working with the Distribution Industry to Review the "One-Third Rule".

The "one-third rule" is a commercial practice that splits the time before a product's expiration date into three periods of equal length, split between manufacturer, retail, and finally consumer. This rule can lead to otherwise perfectly edible food being thrown away.

The "one‐third rule" is a commercial practice that splits the time before a product's expiration date into three periods of equal length, split between manufacturer, retail, and finally consumer. This rule can lead to otherwise perfectly edible food being thrown away.

The Meiji Group is working within industry associations to review time frames for product delivery. We continue to work with retailers to relax the "one-third rule" to a "one-half rule".

In the future, we will continue with this three‐pronged approach: working to relax the "one‐third rule", extending best before dates, and moving to "Year/Month" labelling.

Cooperation with Related Organizations

Cooperation with the All-Japan Food Bank Promotion Council

Working together with related organizations, the Meiji group are continuing our efforts to reduce food waste.

Specifically, in collaboration with food bank organizations through the All-Japan Food Bank Promotion Council, we have begun donating products such as confectionery, pouch curry, and jelly drinks to food banks from January 2019. From June 2019 we also began donating our emergency food supplies that are approaching their best before dates, for regular use at food banks.

Cooperation with the WFP

Meiji Co., Ltd. began its special sponsorship of the Japan Association for the United Nations World Food Programme's "Zero Hunger Challenge" campaign in 2020. Since the campaign was rebranded as the "Gochisousama Challenge" in 2022, we have continued our support as special sponsors. This initiative connects Japan’s efforts to reduce food loss with support for school meal program in developing nations.

Collaboration with the Consumer Affairs Agency

Meiji Co., Ltd. enlighten reducing food loss by placing on its product packaging our humorous poem that won a prize in the humorous poem contest which is the Consumer Affairs Agency's initiative to reduce food loss.

Reduce Final Disposal Volume

We are dedicated to protecting the environment and contributing to the realization of a sustainable, circular society. To achieve this, we strive to efficiently utilize limited natural resources and further reduce the volume of final disposal. Our initiatives include controlling waste generation, collecting and separating recyclable materials, and minimizing the volume and thickness of containers and packaging.

Reduction of Waste Generated at Factories

The entirety of Meiji Group is focused on taking action to reduce the amount of waste generated.

Meiji Co., Ltd. has reduced production waste by 24 tons annually by modifying the pan release oil-spraying nozzle* used in Galbo chocolate production to change continuous operation to intermittent operation.