Natural Taste Process

Removal of oxygen in milk prior to pasteurization eliminates the oxidation products which lead to undesirable off tastes. Consumers are able to taste the difference. This revolutionary technology is called the Natural Taste Process.

The Natural Taste Process Eliminates Oxidative Changes to Milk

Previously, the improving the taste of milk was limited to changing milk fat content or sourcing of raw milk from specific farms. Otherwise it was difficult to make improvements that the customer was able to distinguish.

Milk is produced only from raw milk and no other ingredients can be added. However, we started work toward developing a milk that customers would be excited about and think is delicious.

The Goal was to Produce a Milk as Delicious and Fresh as can be Found on the Farm

Oxidation is the main factor that impairs the taste of food. When milk is pasteurized in the presence of oxygen, a cooked odor and undesirable flavors results from the development of oxidized compounds (sulfur containing compounds, etc.).

As a result of many years of research on milk flavor, Meiji was able to develop a process where oxygen is removed from milk prior to pasteurization, thus eliminating the off-flavors that otherwise develop. This is called the Natural Taste Process. The result is a milk that feels both natural and refreshing, with a clean aftertaste.

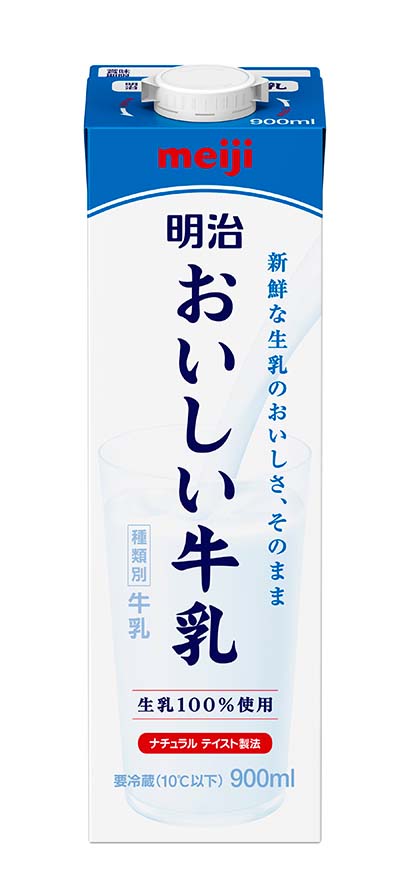

Meiji "Oishii Gyunyu" or "Delicious Milk" is produced using the Natural Taste Process

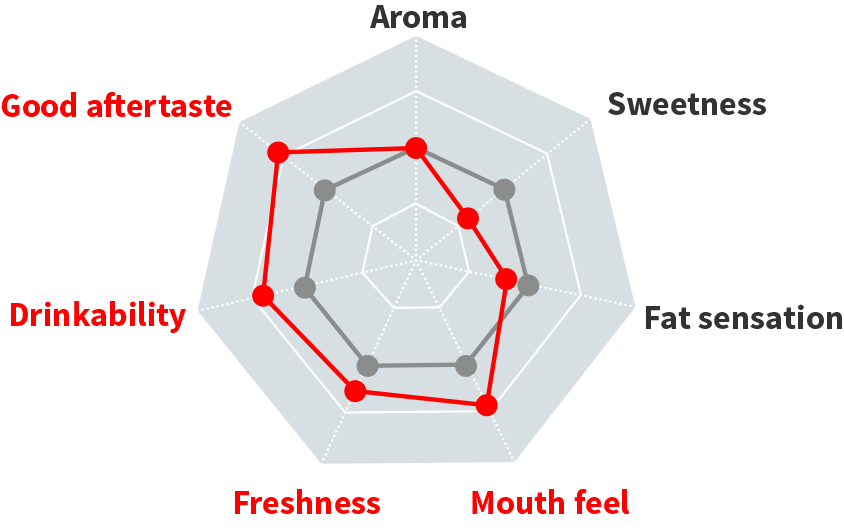

Taste benefits of deoxygenized pasteurization

- Oxygen level during storage 1.5ppm

- Standard products 10ppm

30 person specialist panel

Patent No.:JP3083798 and JP3091752