We want to challenge what people think of yogurt and make something even tastier. The Maroyaka Tannen Fermentation technique was innovated as a method of mild, low-temperature, but thorough fermentation. It was born from the passion of these researchers, which has made it possible to produce a smooth textured and mildly flavored yogurt, closely replicating a traditional Bulgarian style.

In Bulgaria, traditional yogurt is made by fermenting warm milk and a starter culture in an unglazed clay pot. The porous clay absorbs the milk's moisture and concentrates it. As moisture evaporates from the surface of the pot, it absorbs latent heat, triggering a low-temperature fermentation. The resulting yogurt is smooth and rich.

Using the Maroyaka Tannen Fermentation technique, it's possible to reproduce this flavor on an industrial scale. This production method is currently used for Meiji Bulgaria Yogurt LB81 Zero-Fat Plain, Meiji Probio Yogurt R-1 Low-Fat, and others. Meiji researcher, Hiroshi Horiuchi, is behind the development of this technology that has enhanced the flavor of the much-loved yogurt.

Unprecedented technological research and the challenge ahead

Horiuchi started working on yogurt research and development back in 1998. At that time, he says, the commonly held belief in the industry was that you couldn't alter the taste or texture of plain yogurt without changing the lactic acid bacteria strains used.

However, changing the lactic acid bacteria was out of the question, since Meiji Bulgaria Yogurt was certified and had already earned a reputation for its health benefits, which were tied to that particular strain. Meiji still wanted to expand their offerings and develop a new series of yogurt using the same bacteria. Since Meiji wanted to develop a new series of yogurt using the same bacteria, it tasked the research team with creating new flavors and textures without altering the type of bacteria.

At that time, the bulk of research on yogurt in the industry was dominated by the function of lactic acid bacteria. I thought that if we could do research and development on production technology and elevate it to an academic level, then we could really do something interesting that challenges conventional beliefs.

Starting from unexpected experiment results

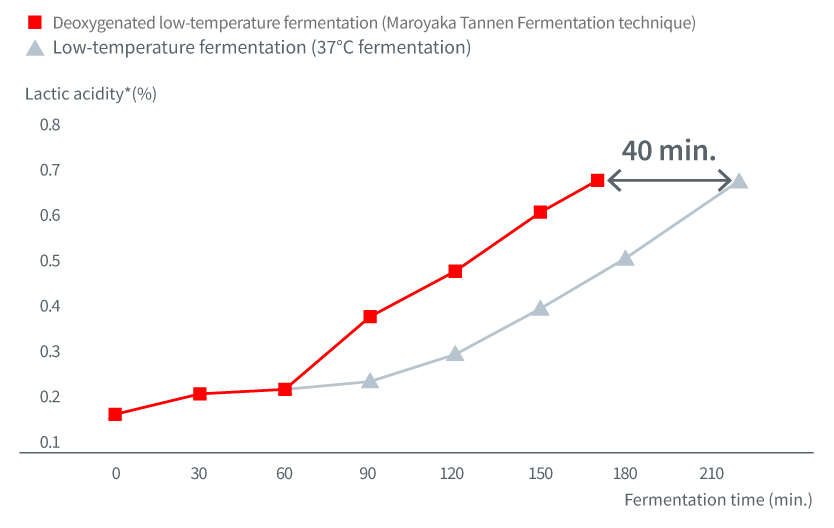

Our research was initially inspired by the technology behind Meiji Oishii Gyunyu milk, which achieves a unique taste by removing the oxygen from the milk before pasteurization. We wondered if we could apply the same process to improve the taste of yogurt. We tried some experiments but weren't really happy with the results, as the taste didn't change. On the other hand, we stumbled on something unexpected—a change in the fermentation time. The process proceeded at a much faster rate. A subsequent experiment revealed that fermentation further accelerated when oxygen was removed immediately before or after adding the lactic acid bacteria or starter.

The research results didn't give us the taste we had expected, but our discovery piqued our curiosity, leading us to low-temperature fermentation.

Yogurt is normally fermented at a temperature of 40 degrees Celsius or higher. Traditional Bulgarian yogurt, however, ferments in clay pots at a much lower temperature which gives it its unique smoothness. It's long been known that the low temperature lends to the texture. In the past, we tried numerous times to apply low-temperature fermentation industrially but could not make it work efficiently. The fermentation was slower than usual which made production inefficient. Additionally, the yogurt curds were too soft and couldn't withstand transportation.

So, we thought that if we started out by using deoxygenated milk in the beginning of the process, that we might be able to shorten fermentation time even at low temperatures. With this idea in mind, we continued our research.

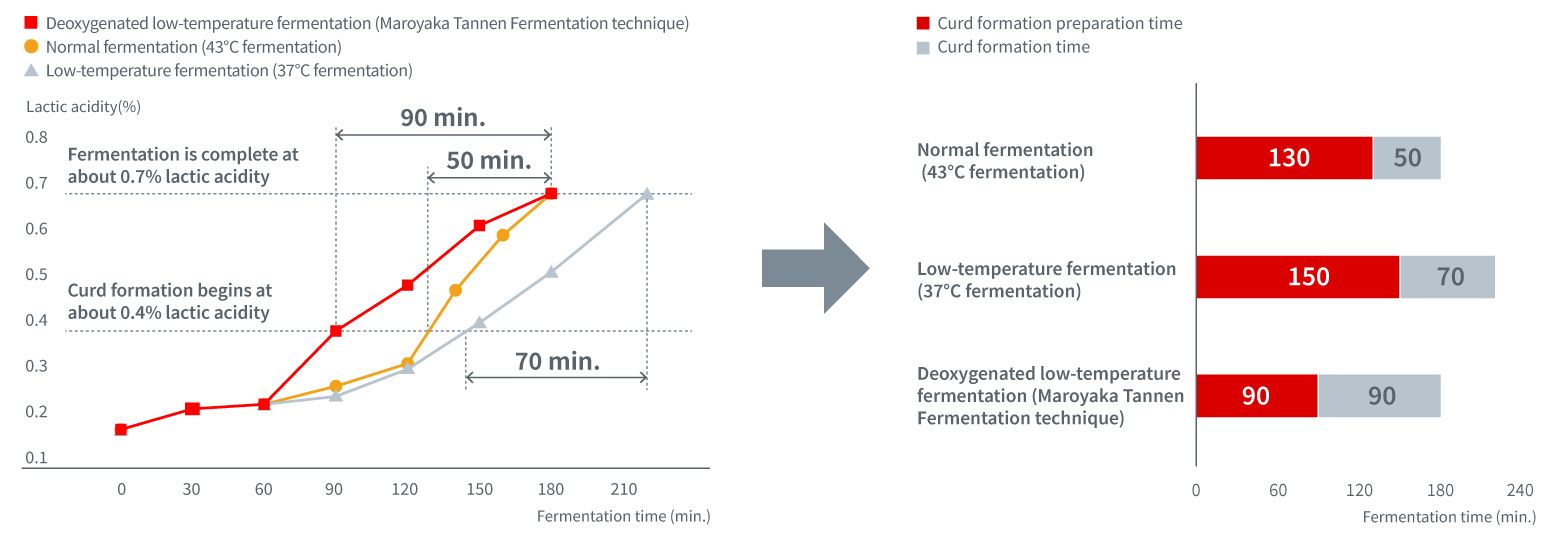

Shortened fermentation time using a deoxygenated low-temperature fermentation (Maroyaka Tannen Fermentation technique)

We found that doing it this way fulfilled the efficiency requirements in production, and yielded a yogurt with a firmer texture and quality that exceeded our expectations.

Through our experimentation, we have developed and perfected the Maroyaka Tannen Fermentation technique that allows for the yogurt to be produced industrially with the same velvety texture and rich flavor of the traditional method.

Curd formation time during fermentation

The technology we developed is in line with nature

How could Maroyaka Tannen Fermentation shorten fermentation time? As we dug deeper the answer to this question became more clear. When Bulgarian bacteria strain (Lactobacillus delbrueckii subsp. bulgaricus) and thermophilic bacteria (Streptococcus thermophilus), traditionally used in yogurt production, are added to milk, they work symbiotically to promote each other's growth and facilitate fermentation.

At closer examination, these two lactic acid bacteria revealed that they first remove oxygen from the milk and then immediately go into fermentation. So by starting out with deoxygenated milk, we were able to shorten the process.

This newly developed technique aided fermentation through the symbiosis of lactic acid bacteria, which has been around since the origin of yogurt thousands of years ago.

Enhancing taste with evolving technology

In 2004, Meiji released the Meiji Bulgaria Yogurt LB81 Domashno, the first to feature the Maroyaka Tannen Fermentation technique. It was soon applied to other products, including low-fat yogurt. Over the past 20 years, the variety of plain yogurt has expanded and evolved in flavor, thanks to Horiuchi's enthusiasm and ingenuity. Horiuchi's dedication to improving flavors has earned him numerous accolades, including the prestigious Invention Prize at the National Commendation for Invention in 2023, which honors the exceptional inventions of researchers, scientists, and others.

The first product using Maroyaka Tannen Fermentation technique, Meiji Bulgaria Yogurt LB81 Domashno

Current products using the Maroyaka Tannen Fermentation technique

In 2023, Meiji Bulgaria Yogurt LB81 Plain underwent its first major revamp in nearly a decade, by combining the newly developed Kuchidoke Hojun Fermentation process with the Maroyaka Tannen Fermentation technique. The Kuchidoke Hojun Fermentation process involves a pre-fermentation technique combining ultra-high temperature sterilization and refined fat content to enhance the yogurt's smoothness and mouthfeel. This approach also produces yogurt with a firmer texture, which was challenging in the past. Incorporating this pre-fermentation technology with Maroyaka Tannen Fermentation, has resulted in an even tastier plain yogurt.

I was pleasantly surprised to find Kuchidoke Hojun Fermentation, a technique developed by a junior researcher. It takes simple plain yogurt to the next level.

The advancements of these two techniques revolutionize conventional yogurt wisdom, as researchers continuously explore new technologies that go beyond the achievements of their predecessors.

The quest to advance these technologies will spur further research. It's entirely possible that with breakthroughs within the span of the next decade, plain yogurt will have also consistently grown even tastier along with each innovation.

The mysteries of the mechanism behind Maroyaka Tannen Fermentation and Kuchidoke Hojun Fermentation are still unsolved and the journey of discovery continues. With the determination to pass on the technologies to future generations, Horiuchi hopes to influence the yogurt industry with this technique for many years to come.