Climate Change

Our Climate Change Targets

Meiji Group 2026 Medium-Term Management Plan

- Data target range or company leading initiatives: Meiji Group Consolidated

| Major initiatives | Metrics | Results | Targets | Medium to long-term targets | ||

|---|---|---|---|---|---|---|

| FYE March 2025 | FYE March 2027 | FYE March 2031 | FYE March 2051 | |||

| 1 | Reduce Scope 1 and 2 CO2 emissions by strengthening energy saving and energy creation activities, utilizing carbon credits, etc. | Scope 1, 2 emissions reduction rate (compared to FYE March 2020 as year of reference) |

25.0% | 32% or more | 50% or more | Carbon Neutral |

| 2 | Reduce CO2 emissions in Scope 3 by reducing GHG emissions in dairy farming, reducing the amount of packaging materials used, and strengthening collaborations with suppliers, etc. | Scope 3 emissions reduction rate (compared to FYE March 2020 as year of reference) |

11.1% | 15% or more | 30% or more | |

| 3 | Promote the transition to renewable energy by expanding the adoption of solar power generation equipment and strengthening the use of electricity derived from renewable energy | Renewable energy ratio | 24.2% | 30% or more | 50% or more | 100% |

Position on Climate Change

The impact of global warming from climate change has resulted in a number of abnormal weather phenomena, including heat waves, dry spells, and concentrated heavy rains. These have caused great damage to the natural environment, including droughts and flooding. The Meiji Group recognizes climate change as a crucial social issue that must be resolved. This is because the Group's business operations originate from the bounty of nature through our value chain.

In light of the IPCC-issued Special Report on Global Warming of 1.5°C, the Meiji Group has aligned its reduction targets of the entire value chain (Scope 1, 2, and 3) for CO2 emissions by 2030 in accordance with the Science Based Targets initiative (SBTi). In September 2021, our targets were certified by the SBTi as being well below 2°C. Furthermore, by raising the targets, we have obtained certification for the "SBT 1.5°C " target in June 2023.

The Meiji Group supports the Paris Agreement, and Japanese laws pertaining to climate change, such as the Act on the Rational Use of Energy and the Act on Promotion of Global Warming Countermeasures, and reports on its progress toward achieving medium- and long-term targets for greenhouse gas emissions and energy consumption every fiscal year.

To encourage greater CO2 reductions, we introduced an internal carbon pricing system in October 2021.

Looking to the future, our efforts to mitigate climate change will continue, and we will focus on introducing energy-saving measures, making use of solar power technology, and purchasing electricity from renewable sources and reducing Scope 3 emissions through collaboration with suppliers and production sites. Meiji Group's target is to attain carbon neutrality by 2050, and we will continue to work towards further reducing greenhouse gas emissions.

CARBON NEUTRALITY BY 2050

Participation in trade associations and Initiatives

The Meiji Group is a member of the Japan Food Industry Center and actively participates in its Sustainability Committee. This center submits policy proposals to the government on critical issues facing the food industry, aiming to promote its healthy development. Through these activities, we are indirectly lobbying government policies on key issues.

Additionally, to stay abreast of the latest information on climate change, we actively participate in seminars organized by government agencies such as the Ministry of Economy, Trade and Industry, the Ministry of the Environment, and the Ministry of Agriculture, Forestry and Fisheries, as well as industry associations. This ensures that our climate change strategies remain consistent with national and industry trends.

Furthermore, we regularly check our climate change strategies and the activities of the organizations we affiliate to ensure alignment between them. If any discrepancies are identified, they are discussed and resolved in the Group Environmental Conference, which is linked to the Group Sustainability Committee chaired by our CEO. This process ensures consistency between our climate change policies and the positions of the organizations we affiliate.

Reduce CO2 Emissions

| Unit | FYE 3/2021 | FYE 3/2022 | FYE 3/2023 | FYE 3/2024 | FYE 3/2025 | |||

|---|---|---|---|---|---|---|---|---|

| Energy consumption volume (Japan) | oil:10,000 kL | 24.8 | 24.0 | 23.5 | 21.5 | 20.5 | ||

| TJ | 9,766 | 9,424 | 9,236 | 8,315 | 7,928 | |||

| Per unit of sales2 | TJ/hundred million yen | 0.9 | 0.9 | 1.0 | 0.9 | 0.8 | ||

| Energy consumption volume (Global) | Electricity consumption | MWh | 631,404 | 772,659 | 760,199 | 757,827 | 774,477 | |

| Unit | FYE 3/2021 | FYE 3/2022 | FYE 3/2023 | FYE 3/2024 | FYE 3/2025 | |

|---|---|---|---|---|---|---|

| Japan | ten thousand tons of CO2 | 46.9 | 43.7 | 42.4 | 36.5 | 35.0 |

| Overseas | ten thousand tons of CO2 | 9.4 | 9.9 | 9.1 | 10.6 | 11.6 |

| Total | ten thousand tons of CO2 | 56.3 | 53.6 | 51.5 | 47.1 | 46.2 |

| Per Unit of Sales2 | t-CO2/hundred million yen | 47.2 | 44.8 | 48.4 | 42.7 | 40.0 |

(Unit: ten thousand tons of CO2)

| FYE 3/2021 | FYE 3/2022 | FYE 3/2023 | FYE 3/2024 | FYE 3/2025 | |

|---|---|---|---|---|---|

| Japan | 21.5 | 22.1 | 20.5 | 17.7 | 17.3 |

| Overseas | 2.4 | 2.4 | 2.4 | 3.2 | 2.8 |

| Total | 23.9 | 24.5 | 22.9 | 20.9 | 20.0 |

(Unit: ten thousand tons of CO2)

| FYE 3/2021 | FYE 3/2022 | FYE 3/2023 | FYE 3/2024 | FYE 3/2025 | |

|---|---|---|---|---|---|

| Japan | 25.4 | 21.6 | 21.9 | 18.8 | 17.7 |

| Overseas | 7.0 | 7.5 | 6.6 | 7.5 | 8.5 |

| Total | 32.4 | 29.1 | 28.5 | 26.3 | 26.2 |

(Unit: ten thousand tons of CO2)

| Category | FYE 3/2021 | FYE 3/2022 | FYE 3/2023 | FYE 3/2024 | FYE 3/2025 |

|---|---|---|---|---|---|

| Japan | 294.8 | 302.7 | 348.4 | 420.5 | 415.3 |

| Overseas | 18.7 | 20.0 | 42.1 | 46.0 | 48.9 |

| Total | 313.5 | 322.7 | 390.5 | 466.5 | 464.1 |

Improved Environmental Data Management

We continue to improve our environmental data management system, which provides evidence of our initiatives dealing with climate change and global warming. In addition to consolidated group data collection and disclosure, we have an independent entity draft group management standards and perform audits to verify our environmental management system operations, as well as improve our data transparency and reliability.

Independent practitioner's assurance

We have obtained the independent practitioner's assurance for the energy consumption volume (Global), the CO2 emissions Scope 1 (Global), the CO2 emissions Scope 2 (Global) and the CO2 emissions Scope 3 Category 1 (Japan) in FY2023 by Deloitte Tohmatsu Sustainability Co., Ltd. to improve the reliability of the data.

Promotion of calculation of the carbon footprint of product (CFP)1

The Meiji Group calculates and visualizes GHG emissions in each process to help prioritize initiatives.

As specific initiatives for the dairy sector, we used methods unparalleled within the Japanese dairy industry to calculate CFP (for Meiji Organic Milk). In addition to referencing the Environmental Product Declaration (EPD), a program operated based on international standards, and guidelines issued by the International Dairy Federation (IDF) global Carbon Footprint standard for the dairy sector, we also used actual data from dairy farmers. In the confectionery sector, we participated in the Ministry of the Environment’s model business for the carbon footprint initiatives of product and services.

As part of those initiatives, we calculated our CFP for Meiji Milk Chocolate (50g)based on ISO14067.

Moving forward, we will expand CFP calculations to other products and make efforts to reduce GHG emissions with the knowledge gained from these initiatives.

Meiji Organic Milk

Meiji Milk Chocolate(50g)

- Meiji Begins Initiatives to Visualize CO2 Emissions from Meiji Milk Chocolate

- Started to Calculate the Carbon Footprint of Milk Production, the First Effort in Japan

Energy-Saving Measures

In order to help fight climate change, we are employing energy-saving measures throughout our entire business operation. Our production sites are continuing efforts to make use of and introduce new low-CO2 emission fuels and high-efficiency equipment.

Introduction of Highly Efficient Energy-Saving Equipment

In order to mitigate the impact on the global environment, we are working on energy saving. As part of the initiatives, we are installing highly efficient energy-saving equipment at some of our production plants. Additionally, along with the modification in how we use our equipment, we are aiming for improvements to our operational efficiency, as well as even greater future energy savings.

Energy-efficient transformer at Meiji Seika Pharma's Gifu Plant

Eco-Friendly Logistics Initiatives Such as the Introduction of Modal Shift

The Meiji Group is aiming to reduce energy consumption and carbon emissions by increasing the efficiency of its delivery vehicles.

For urban areas, this involves working to increase the carrying capacity of our trucks. For rural areas, we are working to increase delivery efficiency by sharing deliveries with other manufacturers.

In addition to this, we are focusing on carrying out a transportation modal shift. By moving away from truck-based transportation and towards railway and maritime transportation for our deliveries from Hokkaido to the Tokyo, Nagoya, Osaka areas, we achieved a modal shift rate of 9.6% in FY2023.

We are working to reduce electricity consumption at our transportation centers and distribution warehouses by switching from mercury lighting and fluorescent lighting to LED technology.

Additionally, we are aiming at a reduction in energy usage through switching from CFC refrigerants in our refrigerated warehouses, in favor of highly efficient natural refrigerants, as well HFCs.

Changeover to Low-Emission Vehicles; Fleet Reductions

We began changing our delivery trucks and sales vehicle fleets to eco cars in FY2012. We have also cut down the size of our sales vehicle fleet.

Reduction of Scope 3 Emissions

It will be difficult to achieve carbon neutrality through initiatives of the Meiji Group alone, so we will work together with suppliers and producers to reduce CO2 and other GHG emissions. At present, we are engaging with some ten primary suppliers with whom we have set CO2 reduction targets and have established a system for ascertaining the status of initiatives. Additionally, we are also working with producers upstream in the supply chain.

Action for raw milk and dairy ingredients

The Meiji Group is striving to achieve sustainable dairy farming by working to improve social issues impacting the dairy industry. The GHG emissions resulting from dairy farming (the methane and nitrous oxide (N2O) resulting from cow belching and cow manure) are a social issue. In addition to promoting reductions in GHG emissions, we are aiming to link initiatives to sustainability in the dairy farming industry by positioning reduction initiatives as a new revenue source for dairy farmers.

As part of those efforts, we launched initiatives aimed at reducing N2O derived from manure produced during dairy farming and maintaining the livelihoods of dairy farmers using amino acid-balanced feed, one of the methodologies defined in the J-Credit Scheme1. In August 2023, we participated in the "Doto Carbon Farming Study Group" which promotes carbon farming2 in Betsukai Town, Japanese largest milk producer, as a verification field to reduce GHG emissions in dairy.

Overview of initiatives

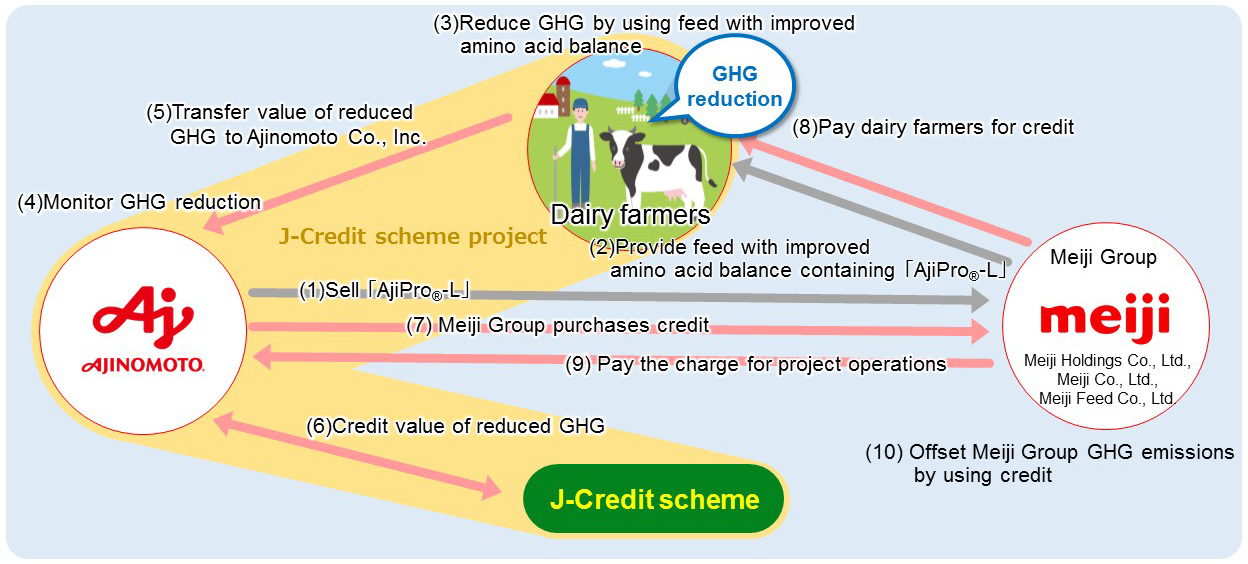

From March 2023, The Meiji group are collaborating with Ajinomoto Co., Inc. to launch a project aimed at reducing N2O derived from manure produced during dairy farming via the J-Credit methodology. Using amino acid- balanced feed enables dairy cows to absorb nutrients more efficiently than conventional feed, limiting the N2O emitted from manure due to the excess nutrients. The reduced GHG emissions will be converted to Credits and purchased by the Meiji Group. We will connect the credits to new revenue sources for dairy farmers and offset GHG emissions related to dairy farming along our entire value chain. We will use these initiatives as a opportunity for expanding future collaborations and promoting GHG reductions.

<Business model based on the J-Credit Scheme>

- The Meiji Group and Ajinomoto Co., Inc. started a collaboration to realize sustainable dairy farming

<The activities of the Doto Carbon Farming Study Group>

The Meiji Group has established the "Doto Carbon Farming Study Group" (hereinafter referred to as "Doto CF Study Group") with General Incorporated Association Doto SDGs Promotion Council1 in order to promote initiatives that lead to GHG emissions reduction in dairy. The Doto CF Study Group will promote evaluation, research, and practice of "Carbon Farming" in Betsukai Town, Hokkaido, the largest milk producer in Japan. The Doto CF Study Group will contribute to the realization of sustainable dairy by increasing GHG storage in soil . This will be the first initiative in Japan in which the local community, local residents, and dairy manufacturers will collaborate to experiment with carbon farming from the dairy and propose to society how the dairy should be in the future. In September 2023, we started a survey of carbon sequestration in the soil at the farms of members of the General Incorporated Association Doto SDGs Promotion Council.

The members of the Doto CF Study Group, including the Meiji Group, also participate in the "Hokkaido Carbon Farming Promotion Council " established (May 25, 2023) by the Department of Agriculture, Hokkaido Government as a forum for information exchange and collaboration among a wide range of stakeholders, including producers, industry, academia, government, and financial institution, with the aim of decarbonizing agriculture in Hokkaido. Through this council, the spread of carbon farming is expected to expand throughout Hokkaido.

Kick-off meeting at Betsukai Town Hall on July 14, 2023

Action for Cocoa

We participate in the Cocoa & Forests Initiative, a global partnership for the protection and restoration of forests, and work with the government of Ghana and related organizations to aid forest conservation. In addition, we are working with cocoa farmers in Tomé-Açu, Brazil, to promote agroforestry farming*, a form of agriculture that creates forests, in our forest conservation work.

As Meiji Cocoa Support, our unique cocoa farmer support program, we donate wells, distribute free seedlings, and provide guidance on farm management, activities leading to the conservation of forests that will sequester CO2.

*"Agroforestry farming:" A combination of the words "agriculture" and "forestry." This is an agricultural method in which a diverse set of agriculture and forestry is cultivated in keeping with the natural ecosystem on land after trees have been harvested.

Action for Palm oil

Promoting replacement to RSPO-certified palm oil

We have achieved 100% replacement to palm oil certified by the Roundtable on Sustainable Palm Oil (RSPO) by FY2023. This helps prevent deforestation, thereby promoting CO2 capture.

Action for Plastic

By reducing the weight of plastic containers and packaging, we are working to reduce CO2 emissions during product manufacturing, delivery, and disposal. We are also working with suppliers and others to switch their container and packaging raw materials from fossil fuel-derived plastics to recycled plastics and bioplastics, which have a smaller environmental impact, while still ensuring product quality.

In February 2021, we began blending bioplastics into straws, plastic cups, and other containers and packaging. Furthermore, from July 2022, we will gradually switch to bioplastics for use in the caps of Meiji Oishii Gyunyu and other products. As a result, we aim to reduce CO2 emissions from containers by approximately 10% to 15%* compared to conventional methods.

*Our CO2 reduction rate is certified by Carbon Trust.

Action for paper raw materials

By FY2023, we have switched 100% of product containers and packaging materials to eco-friendly paper raw materials (FSC® -certified or other forest certified paper, including recycled paper). This helps prevent deforestation, thereby promoting CO2 capture.

Adopted an Internal Carbon Pricing System

The Meiji Group has adopted internal carbon pricing (ICP) system for the Meiji Group's capital investments in energy-saving equipment and other equipment that contribute to reducing CO2 emissions. We have set our internal carbon price at (15,000 yen/t-CO2).

An internal carbon price will be applied to estimate the cost of CO2 emissions. We will use the calculated costs as one of the decision criteria for capital investment plans that entail an increase/decrease in CO2 emissions. By adopting this system, we can now measure financial impact and reduce CO2 emissions.

Promotion of Renewable Energy

Renewable power sources like solar, wind, and biomass power not only help reduce consumption of non-renewable resources like petroleum, they also help us curtail emissions of greenhouse gases like CO2. The Meiji Group is helping to fight climate change through various energy-related initiatives.

Introduction of renewable energy generation facilities, including solar generators

The Meiji group are working to reduce our CO2 emissions by installing renewable energy generation facilities, such as solar panels. As of March 31, 2025, 22sites in Japan and overseas are using electricity from renewable energy sources such as solar and wind power generation. The annual reduction in CO2 emissions from solar power generation facilities amount to 5,424 t- CO2 in FY2023. We are planning further installation of renewable energy generation facilities in the future, both in Japan and abroad.

Sites Fitted with Solar Power Generating Equipment in FY2023

Moriya Plant (Operations commenced in July 2024.)

Purchase of electricity from renewable sources

We are also systematically purchasing electricity from renewable sources.

From 2018, Medreich Limited (India) has been purchasing electricity generated by solar technology.

From 2019, Medreich PLC (United Kingdom) has been purchasing 100% of its electricity from wind-power generated sources.

From April 2021, Aichi Plant of Meiji Co., Ltd. ,and from April 2022,Tokai plant began purchasing 100% renewable electricity.

Use of bioenergy

Sakado Plant of Meiji Co., Ltd. and Meiji Chewing Gum make use of methane biogas as fuel, for example in its boilers.

In addition, at Meiji Co., Ltd. Tokachi Factory, we installed equipment that uses methane fermentation to treat wastewater from whey residue generated during cheese production. The introduction of this equipment is expected to reduce the annual amount of industrial waste at the Tokachi Plant by approximately 54%* and CO2 emissions by approximately 5.9%*.

Eliminate Specific CFCs

Promotion of Converting from CFCs to Natural Refrigerants, As Well As HFCs

The use of CFCs has become an important issue, due to their ability to trigger ozone depletion, thus greatly speeding up climate change.

Following the guidelines of the Montreal Protocol, we perform periodic inspection of facilities that make use of CFCs, in order to reduce the risk of CFC leakage. At the same time, as part of our climate change initiatives, we are continuing to switch over from CFCs to natural refrigerants.

We are working to completely eliminate CFC-using equipment by FY2030.

Cases of Switching to Natural Refrigerants

The Meiji Group is aiming to further reduce CO2 emissions by introducing new energy-saving machines that use natural refrigerants. We are actively making use of subsidies from the Ministry of the Environment for this purpose.

- Meiji Co., Ltd.

- FYE 3/2016: Kyoto plant, Gunma plant

- FYE 3/2018: Kyushu plant

- FYE 3/2019: Kyoto plant, Moriya plant, Tokai Meiji

- FYE 3/2020: Kanagawa plant, Moriya plant, Nagano depot, Tokai Meiji

- FYE 3/2021: Toda Plant, Tokai Plant, Shikoku Meiji(Kagawa Plant)

- FYE 3/2022: Moriya Plant,Nagano Cheese Plant

- FYE 3/2023: Osaka Plant, Gunma Nutritionals Plant, Kansai Plant,Kansai Ice Cream Plant,Kyoto Plant,Saitama Plant, Wakkanai Plant, Toda Plant

- FYE 3/2024: Kansai Plant, Kyoto Plant, Nagano Cheese Plant, Kyushu Plant, Toda Plant

- Meiji Seika Pharma

- No cases after FY2015

- KM Biologics

- FYE 3/2016: Kumamoto plant

- FYE 3/2022: Kumamoto Production Center,Kikuchi Reserch Center,Koshi Production Center,Aso Production Center

- FYE 3/2023: Kumamoto Production Center,Kikuchi Reserch Center,

- FYE 3/2024: Kumamoto Production Center